Despite being in the midst of a slow-motion bankruptcy (or so it seems, someone send me a Morgan to work on!), I’ve been looking to buy a welder. The last welding job I farmed out was both expensive and the work so bad the piece is unusable (sadly, it’s the right front wing on the ’55 Morgan). After just a few weeks (ahem) of looking, Craigslist has coughed up a used example for me to burn holes in metal with. Fixing that awful fender work will be the first thing tackled when I have figured out how to use the thing.

When buying used tools, I like to try and find high-end stuff for a discount–but owners of welders (and lathes) seem to consider beat-up and well-used to have the same value as new. (Why I would buy a used welder for very nearly the price of the exact same unit new, especially when new has a warranty?) I saw several ads over the weeks where the used welder was priced above the cost of the exact same thing new. People are weird.

Anyway, this Eastwood 175 (it’s a MIG machine, and not a high-end one, just to be clear) was listed for $400, and I paid the asking. Not a bargain, but compared to other used and similar machines new, a decent deal. The closest new machines in specification would be over a grand. It was really grubby, but seemed to otherwise be complete and the dude who owned it was a decent sort, which is not to be under-valued.

The welder came with an unused spool gun, apparently allowing the welding of aluminum (with the right gas and wire), which is nice to have in pocket. Additionally, an auto-darkening helmet and cart, both cheap-but-serviceable Harbor Freight items, were included.

But the real gem included was a 25′ extension cord–with a welder outlet on one end, and a four-prong NEMA plug on the other, allowing the welder to be plugged into a generator. It also allowed me to put a NEMA outlet just below the breaker panel in the shop (which is a fair distance from where I’m likely to use the machine), for a fairly painless solution to the “how are we going to power this” problem. 25 feet gives me a lot of flexibility as to where I can burn holes in stuff.

(Said cord would cost at least $100 to build using materials from my local hardware store–6 gauge rubber-sheathed four-wire cord is several dollars per foot, the welder outlet would be about $40, and add $20 for the NEMA plug.)

The tank regulator and gas connection hose were still with the welder–the previous owner only welded with flux-core wire, so they were unused. I stopped at Central Welding and bought a 92-cubic-foot gas bottle, filled with a CO2/Argon mix for mild steel. The bottle, filled, was $250. That size bottle (apparently) will last for about three solid hours of welding–or months of me dinking around.

With a 30-amp circuit breaker, Romex 10-gauge wire, a NEMA outlet, some welding gloves and such, I’m all-in about $800.

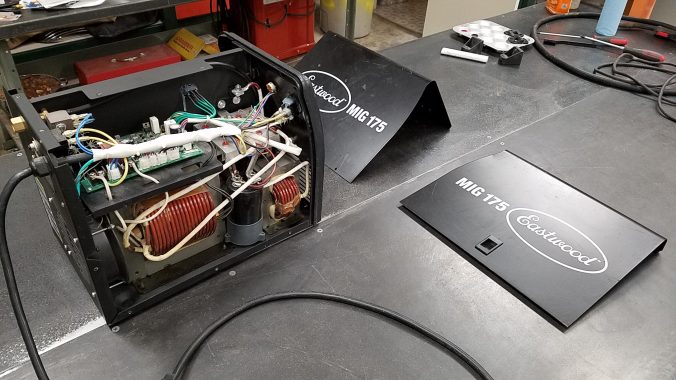

Once home, I took the cover off the unit, to look for any signs of electrical distress, and to blow the dust out. I turned the bolts around on the top tray of the cart so the welder actually fit (it was too wide with the bolts pointed in), and put a piece of 1/2 ply under the box so the side cover can be opened without lifting it off the cart.

People who can weld should look away at this point.

I grabbed a piece of 20-gauge scrap, just to see if the machine would strike an arc, not trip a breaker while doing so, check if the helmet actually auto-darkened, etc., etc. and went to “work”. Welp. There is exactly one bead in this collection I would call semi-serviceable, top center. It’s clear there is going to be a bit of a learning curve…but I’ve got lots of scrap steel to practice on. Though what it did to deserve that is beyond me.

The circuit board has a 2012 date on it…but I was told it mostly sat in storage after a single garden-trellis project. A bit like me, really.